We are your competent partner for the cost-effective assembly of printed circuit boards. Depending on your requirements, we take over your order from development to the finished circuit board.

Our offer includes:

THT (Through-Hole Technology)

In this method, wired electronic components are inserted and soldered through contact holes in the printed circuit board. Soldering is done by hand or via a surge.

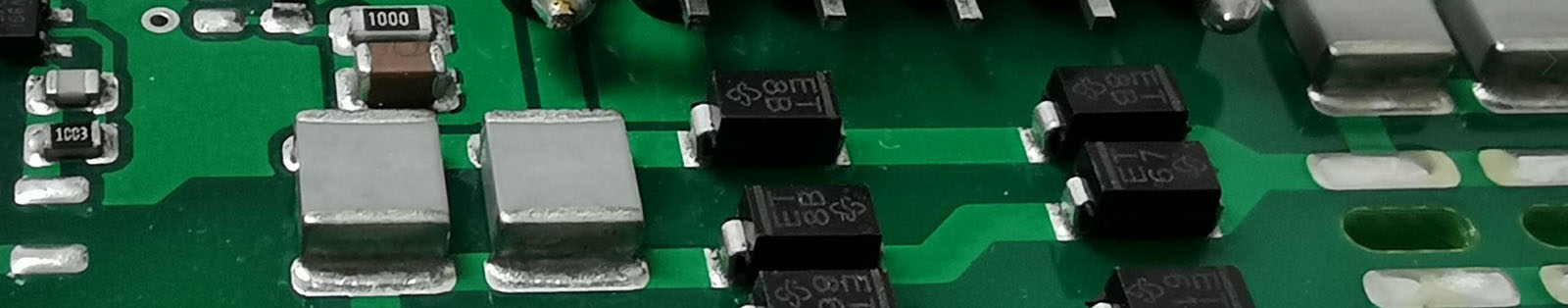

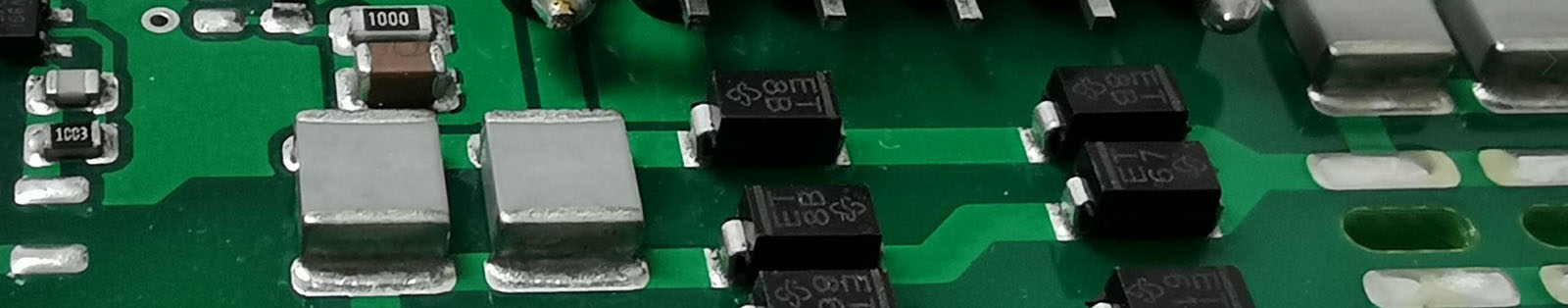

SMD (Surface Mounted Device)

During surface mounting, SMD components are soldered directly to the circuit board using solderable contact surfaces. This makes it possible to achieve a very dense configuration and, above all, a double-sided mounting of the printed circuit board.

Mixing equipment

THT and SMD components are combined.

Research Center Dresden-Rossendorf | Technical University of Berlin | University of Frankfurt | Society of Heavy Ion Research, Darmstadt | University of Augsburg | Institute for Surface Modification, Leipzig | Research Center Jülich | European Commission, Luxembourg | Institute for Reference Materials and Measurements, Geel, Belgium | Joint Research Center Ispra, Italy | Instituto Nacional de Pesquisas Espaciais, Brazil | CNEA, Argentina | National Accelerator Center, Cape Town, South Africa | Samsung, South Korea | University of Sydney, Australia